Add:No.1,Jingqi Road,Hi-tech Zone, Yantai City, Shandong Province, China

Sales Hotline:+86-18663896299

Customer Service Department:

Tel:+86-535-6726618

Fax:+86-535-6726618

E-mail:haige@haigechina.com

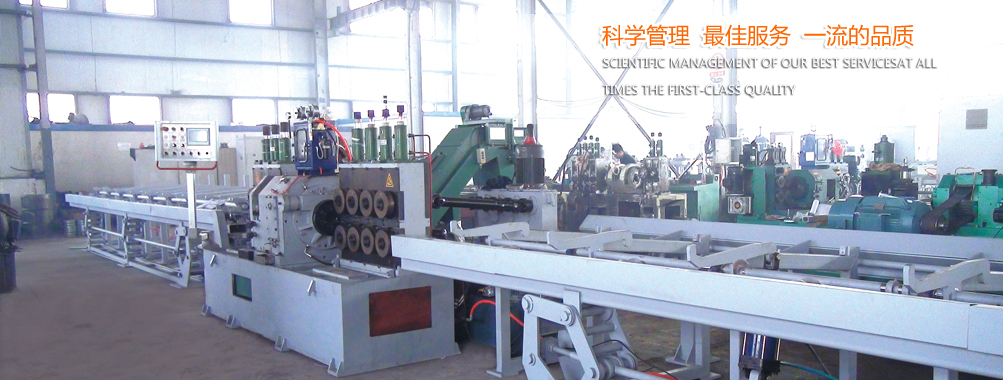

Yantai Haige Machine Tools Co., Ltd. (formerly Yantai Ruihai Machinery Co., Ltd.) is a high-tech enterprise integrating R&D, production and marketing of slender axle finishing equipment. It is situated at Shengquan Industrial Park, Laishan District, Yantai, Shandong. The company mainly deals in centerless lathes (commonly known as stripping machine), straightening machine, abrasive belt grinding machine (polishing machine), screw whirling cutter milling machine and auxiliary machines, which are mainly applicable to automatic bright material production line finishing such as external peeling, straightening and pressure light, polishing and screw processing for steel, copper, titanium, magnesium and aluminum rods, pipes and wire rods. It is the best choice to substitute for traditional pickling and drawing process, traditional turning and grinding process and traditional straightening process as it can rapidly remove surface cracks and defects of oxide layer or decarburized layer of rods and produce high-quality metal polished rods, pipes and wires with high precision and surface roughness. Its efficiency is several times to tens of times higher than conventional process, so that the cost for labor and equipment is reduced.

Right now, the company is ranked as the largest innovative manufacturer of centerless lathes and straightening machine in China. Our products always take a dominant position no matter in design concept, production scale and use quality or after-sales service. It ranks first in productivity and market shares, and comes into the front row in production experience and equipment maturity. The company possesses the professional machining factory and assembly factory, as well as complete set of advanced precision machining equipment for independent production of demanded high-precision core parts. Now, the company owns several CNC machining centers and over twenty sets of large CNC planer type milling machines, CNC lathes, digital readout boring and milling machines, precision grinding machines, CNC cutting machines, CNC drilling machines and common lathes for ensuring machining precision, quality and stability of key parts and timely supply of after-sales parts.

The company sets up a professional technology R&D department which holds advanced R&D capability, software and hardware configuration and large personnel scale. Our professional R&D team keeps pace with the world latest technology to continuously develop new equipment and upgrade the original one, which provides solid technical support and guarantee for leading-edge machine tools we produced. Our complete set of metal finishing equipment is marketable in nearly thirty provinces, cities and autonomous regions in China, as well as Taiwan, South Korea, Russia, India and Vietnam with sophisticated technology, excellent quality, high machining precision, high reliability, high production efficiency, automatic line production and considerate after-sales services. The company is the only enterprise which obtains Quality Permit for Export of Centerless Lathe and Straightening machine in China.

Taking quality as the lifeline, we have passed the certification of ISO9001 Quality Management System and operated in strict accordance with the system.

Haige Complete Set of Automation Equipment is applicable to processing of many metal materials, e.g.

1. Ferrous metals: Stainless steel, bearing steel, spring steel, tool steel, structural steel, alloy steel, free-cutting steel, air valve steel, gear steel, others;

2. Nonferrous metals: Copper alloy, titanium alloy, magnesium alloy, aluminum alloy, etc. Widespread in preparation link in manufacturing of slender axles, hydraulic/pneumatic elements, bearings, springs, auto parts, textile machinery, processing of cold forging materials, instruments, steel pipes, cutters, engineering machinery, sports equipment and other machinery, as well as copper industry, titanium industry, aluminum industry, magnesium industry, petroleum, power and bridge (e.g. piston rod, optical axis, bolt, spring, rack, rod thread, stainless steel rod, copper rod, titanium rod, aluminum rod, magnesium rod, bearing ring, draglink, roller shaft, pin, polishing rod, screw, core rod, oil drill pipe, tightwire, pipe blank).

Our company has formed powerful R&D and production capabilities and a consummate after-sales service system. The company can produce hydraulic semiautomatic and CNC series products in model No. of B, C, CA and S, with to-be-machined diameter from Φ5mm to Φ350mm, and can plan and design metal bars, tubes and wire rods finishing lines to meet customer demands. We are capable of helping customers fulfill digitalized and automated control and management of production, to improve production efficiency and quality fundamentally.

点击或扫描下载

点击或扫描下载